Seal facade

Professional facade sealing is crucial for reliably sealing the facade and ensuring the longevity of a building. Different materials and techniques must be coordinated to achieve a reliable seal against moisture and external influences. Here you will find detailed instructions and best practices for effectively waterproofing your facade, including the correct application of sealing films, adhesives and insulation materials.

Topic overview

Connection to the vapour-open vertical seal

ELEMENTS WITH CIRCUMFERENTIAL INSULATING WEDGE

WINDOW SILLS BY MEANS OF DRAG <BR>FILMS (EXTERIOR)

Parapet connection

Sealing of external corners

Sealing internal corners

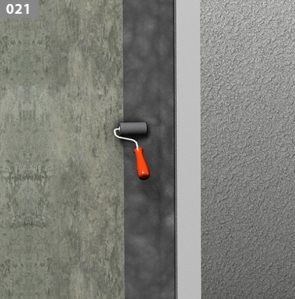

Connection to the vapour-open vertical sealing (TEROSON FO 3)

This prevents capillary moisture from rising, as the adhesive bonds and additionally seals the edge area of the film (017). Then press the foil into the adhesive bed with the hard rubber roller so that the adhesive is pressed apart to the required sealing width (018). The outer insulation of the façade can then be applied, e.g. with insulating wool.

Pre-treatment of the bonding surface with TEROSON SB 450

Type of adhesive application

Rolling the film into the adhesive bed

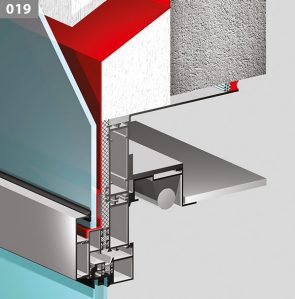

Detail of elements with circumferential insulating wedge

If the facade elements are installed in front of the building structure (in the insulation level), a so-called insulating wedge is planned / installed around a facade element. This insulating wedge must be sealed with a vapour-open plastic foil such as TEROSON FO 3 SK1. The film is rolled onto the frame element with an SK strip and bonded to the building structure with TEROSON AD KDS paste.

Sealing the insulating wedge over the element

Adhesive application

Pressing the film onto the adhesive bed with a hard rubber roller

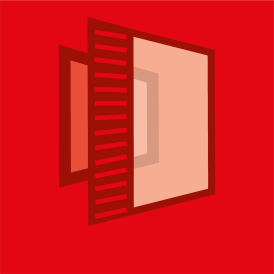

Detail of window sills – in the outdoor area ‘trailing film insert’

Window sills that are installed on the outside of window and facade elements are usually made of aluminium profiles. If condensation is likely to occur underneath the window sill or if the window sill end pieces are not sealed against rain, a second waterproof layer must be created using a sealing film (e.g. TEROSON FO SD3 SK1). The film is adhered to the substructure profile of the window or facade element and guided over the external insulation layer to the water-draining level of the insulation material. The foil must be provided with an overhang (approx. 5 cm) so that the foil cannot fold up and thus prevent moisture from penetrating the insulation material (028). It is not necessary to bond the TEROSON FO SD3 SK to the insulation material.

Foil guide for TEROSON FO SD3 below a window sill

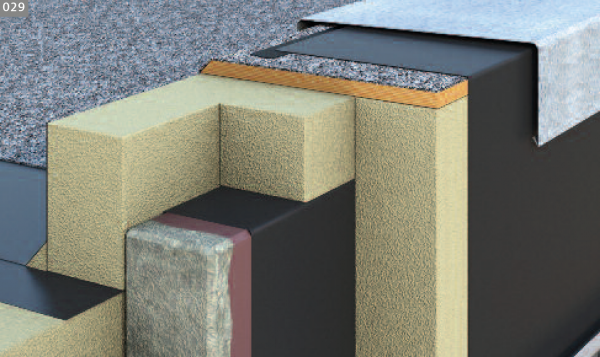

Detail of an parapet connection

The parapet connection of façade elements as the upper connection to the roof is realised on the cold side of the building with TEROSON FO SD150 M+S. The insulation is then applied above the façade element up to the top edge of the parapet. TEROSON FO SD3 SK foil can be bonded as a vapour diffusion-open foil from the facade element to above the parapet on the inside of the parapet with TEROSON AD KDS.

When connecting the TEROSON FO SD3 SK membrane (parapet connection with contact to the flat roof waterproofing), the compatibility of the products that come into direct contact with each other must be checked in advance (029). In addition, the preparation of the substrate must be carried out precisely (primer, adhesive, cleaner, etc.). Cross-trade product compatibility is one of our decision-making maxims.

Parapet connection in detail

Suitable products for sealing:

TEROSON FO KSK M+S

TEROSON FO SD3 / TEROSON FO SD3 SK1 / TEROSON FO SD3 SK2

TEROSON AD KDS

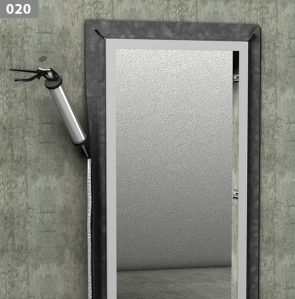

Detail for sealing external corners

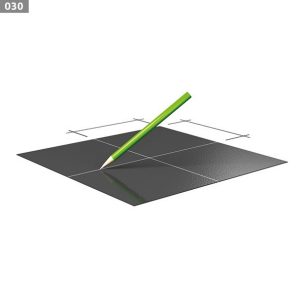

Internal and external corners can be created very easily on site with fully self-adhesive window connection films (can be plastered over or faced). Mark the desired size of the corner to be bonded (030). The various films can then be cut with a cutter knife (031). The first half is then folded outwards. (032). The cut corner is folded inwards. The release paper is then removed from the corner that is still sticking up (033). The second corner with the adhesive compound is now carefully folded onto the other film. Ensure that as few air bubbles as possible are trapped and that the adhesive compound is fully bonded to the other part of the film (033 I 034).

Then roll the glued corner well with a hard rubber roller on a smooth surface so that a firm bond is created (035) and air bubbles are rolled out. Ensure that the tips overlap and are 100% tight. Otherwise a patch should be considered. The release paper can then be removed inside the outer corner and the corner can be glued to the building structure. Depending on the structural situation on site, this work step can also be carried out directly on the building structure. Mineral substrates must be pre-treated with TEROSON PR Primer M+S.

Mark the size of the corner

Cut in with a cutter knife

Folding over the cut film half

Peel off the release paper

Folding over the adhesive surface

Pressing the adhesive surfaces with a hard rubber roller

Detail for sealing internal corners

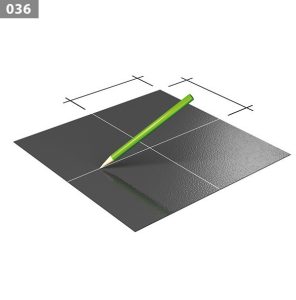

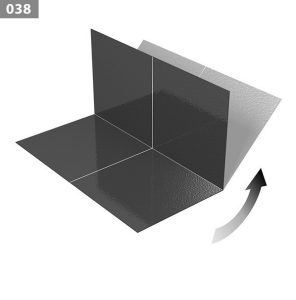

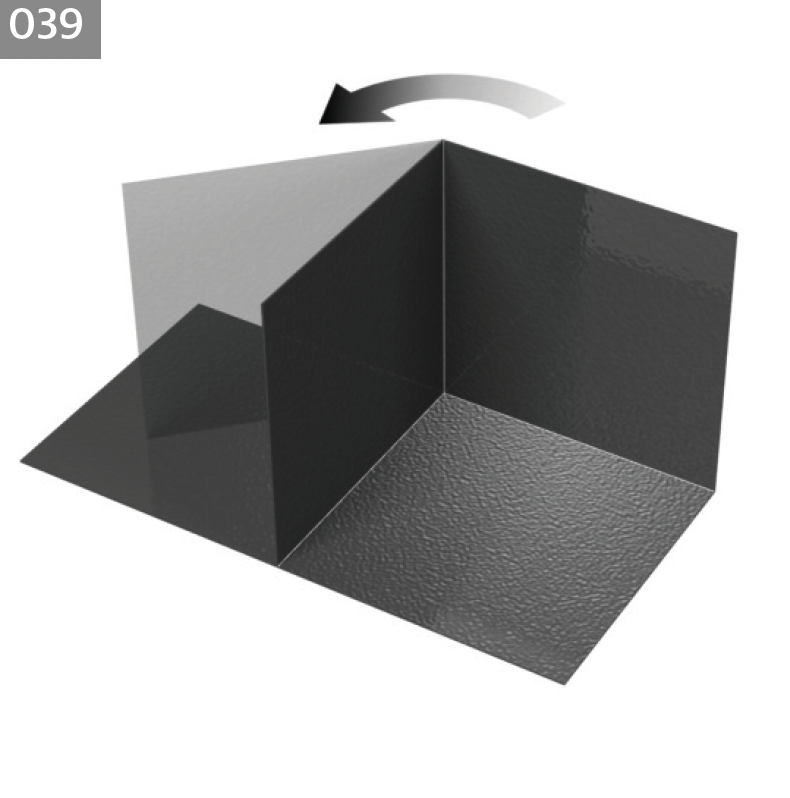

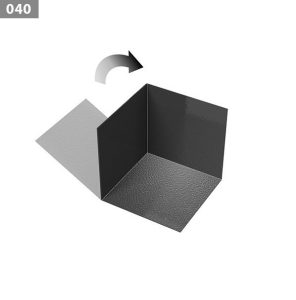

Mark the desired size of the corner to be glued (036). The film can then be cut with a cutter knife (037). Fold one half up parallel to the cut side (038). Then fold in the upper cut part and peel off the release paper (039). Fold up the second half of the cut side. Make sure that as few air bubbles as possible are trapped (040).

Ideally, press the glued surfaces firmly from the outside and inside on a smooth surface using a hard rubber roller (041). The release paper on the outside of the inside corner can then be removed and the corner can be bonded to the building structure. Mineral substrates must be pretreated with TEROSON PR Primer.

Marking the corner

Cutting the film

Folding up the film half

Remove release paper

Folding up the second quarter

Rolling the adhesive surface with a hard rubber roller

This might also interest you

New TEROSON Profi Guide

The TEROSON Profi-Guide is the ultimate, easy-to-read reference work for waterproofing professionals.

TEROSON product range

Download the TEROSON product programme and get detailed information about our products.

Products at a glance

From waterproofing to coating: Discover TEROSON's comprehensive range of products at a glance.

Do you need technical advice?

Our TEROSON team is at your disposal.

Get in touch with us!