Pre-compressed sealing tapes

EXPERT ADVICE:

Incorrect dimensions and lack of attention in the corner joints are the biggest sources of error with this seal.

Application areas

Tightness against driving rain 300/600

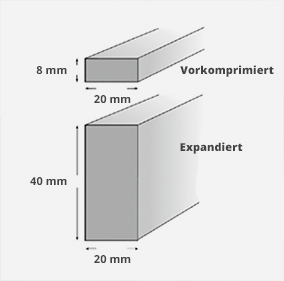

For a building height of up to 20 metres, sealing up to 300 pascals against driving rain is sufficient. For building heights over 20 m (up to 100 m), a tape up to 600 Pascal should be used. TEROSON PT ecoMAX 600 is the ‘all-rounder’ on the market and fulfils all requirements.

Preparation

Backgrounds

Expansion times

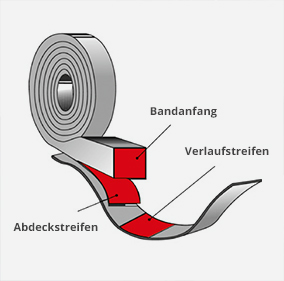

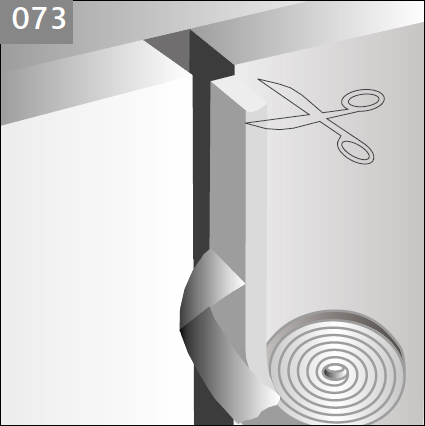

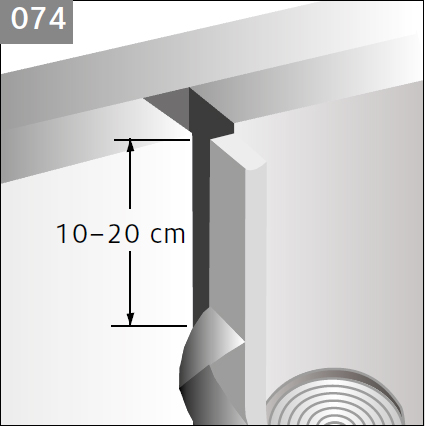

After unpacking, first remove the leader strip from the roll, cut the beginning of the tape straight with scissors and apply immediately afterwards. To do this, remove the cover strip approx. 10-20 cm from the self-adhesive side of the tape (073 I 074).

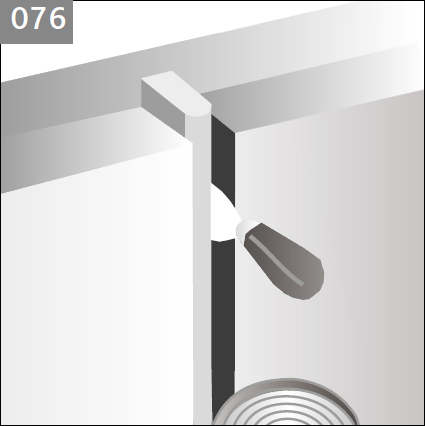

Press the self-adhesive side by hand or with a spatula against the joint edge or the building element/mounting/shy;part, fix it in place and do not pull it to length. Then continue to remove the cover strip from the self-adhesive side according to the work progress. When cutting the tapes to size, add about 1 cm per running metre to compensate for any stretching. For wider joints, the tape should be set back 1-2 mm from the joint edge (075 I 076). After expansion, it adheres firmly to the edges of the joint. Unevenness is levelled out by the elasticity of the joint sealing tape.

EXPERT ADVICE:

As a general rule: heat accelerates expansion, cold slows it down.

An overview of a few advantages and disadvantages of compressed sealing tapes:Advantages

- For exposed masonry

- Good compatibility with mineral substrates

- UV resistance

- No mineral joint primer or dewatering necessary

- Corner joint design difficult

- Limitations in the joint dimensioning

This might also interest you

New TEROSON Profi Guide

The TEROSON Profi-Guide is the ultimate, easy-to-read reference work for waterproofing professionals.

TEROSON product range

Download the TEROSON product programme and get detailed information about our products.

Products at a glance

From waterproofing to coating: Discover TEROSON's comprehensive range of products at a glance.

Do you need technical advice?

Our TEROSON team is at your disposal.

Get in touch with us!