PU insulating foams

EXPERT ADVICE:

The advantage of PU foam over mineral wool is that it is much more even, faster and easier to process.

Advantages and disadvantages of

1-component PU foam at a glance:

- Very efficient

- Simple processing

- Best sound and insulation effect

- No complicated corner formation/stuffing

- Can be processed at low temperatures

- Almost independent of joint dimensions

- Dangerous goods

- Frame soiling with inaccurate foaming

- Cleaning of the PU foam gun necessary

- Moisture necessary

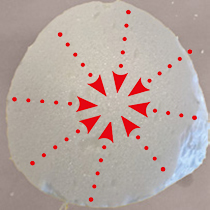

Window insulation with

PU insulating foam in detail

Replacing PU foam cans in detail

Foaming in winter

During the cold season, the processing of PU installation foams can be problematic in some cases. Many PU foam manufacturers specify a minimum processing temperature of +5 °C for their products. The product TEROSON EF 537 is also suitable for processing in the cold season. The foam can be processed down to an ambient temperature of -10 °C. On winter days with low humidity, it is advisable to add additional moisture to the foam. In winter, it is essential to foam the window connection joint first before spraying moisture onto the foam with a spray bottle (083). When spraying the window connection joint before foaming, a layer of ice immediately forms on the masonry, which leads to a loss of adhesion of the 1-component insulation foam to the building.

EXPERT NOTE:

In order to have approximately the same flow rate of the foam as in summer, it is necessary that the can temperature is not colder than 0 °C.

Cleaning PU foam guns

PU foam cans are disposed of in Germany via the PDR system.

EXPERT ADVICE:

PU foam cans should be stored upright in accordance with the labeling on the cartons (085). This ensures the long-term function of the foam valve. During transportation, PU foam cans must be transported in a suitable box on the loading area in accordance with the German Dangerous Goods Transportation Act (GGBefG). Carrying the cans in the rear of the vehicle is not permitted.

This might also interest you

New TEROSON Profi Guide

The TEROSON Profi-Guide is the ultimate, easy-to-read reference work for waterproofing professionals.

TEROSON product range

Download the TEROSON product programme and get detailed information about our products.

Products at a glance

From waterproofing to coating: Discover TEROSON's comprehensive range of products at a glance.

Do you need technical advice?

Our TEROSON team is at your disposal.

Get in touch with us!